-

Your shopping cart is empty!

Menu

Adding gates to your home gives a degree of prestige and style. When closed they are highly visible from outside and inside the property. They can be made from a variety of materials and there’s a style to suit any property. Gates can be manually operated, or they can be automated with a system of motors, safety devices and access control equipment.

Manual gates do their job for a while until the novelty of opening and closing them by hand wears off. Then, they’re left open and might as well not be there, as gates are much less obvious when open, and they don’t control access to the property.

With gate automation, gates can be opened and closed from the comfort of your home or car with a variety of devices depending on your system. No more getting out of your car in the rain to unlatch and push your gates open, driving through them and then getting back out of your car to close the gates behind you.

Automated gates provide a level of security that is impossible with manual gates. Even the simple fact that they are left closed, rather than wide open, can deter opportunistic thieves. But their role as a provider of property security comes with a few caveats.

Because automatic gates can be left closed while the homeowners are inside or away from the property, entry through the gates is controlled. This means that access should only be given to approved visitors, and undesirables are kept out. However, in regular operation, granting access to a vehicle driven by an approved visitor also allows undesirable passengers to gain entry.

If gates move slowly enough to allow a second car to tailgate an approved car through before the gates shut, a pedestrian waiting by the gates can also dart through. And anyone agile enough to climb over gates doesn’t worry if they’re closed.

There are also situations where automatic gates should open to allow access to emergency vehicles. If a fire alarm is activated, the gates should open to allow fire services onto the property. But if a burglar alarm is activated, should the gates open or stay shut?

Video intercom access control systems provide the ability to see visitors before approving their entry by opening the gates. This increased level of security can even work from anywhere in the world via mobile phones where GSM systems are installed.

There are definitely security advantages that automatic gates provide over manual gates, but security is not a primary benefit automated gates deliver.

Press stories featuring automatic gates don’t often make headline news and when they do it’s usually following an accident caused by unsafe gates. There are undoubtedly safety considerations when designing and installing automatic gates, but the additional safety provided by automating gates is often ignored.

Gates that are closed help prevent young children and pets chasing balls into busy streets. They also keep them out of view of passers-by and behind an obstacle that deters spur-of-the-moment access by undesirables.

The safety issues that can be caused by badly designed and installed automatic gate systems are considerable. This subject warrants its own section and is covered later in this guide.

One of the first things visitors see is the entrance they will pass through to get onto the property. If there are gates at this entrance, these are going to create a first impression.

Choosing the right gates can considerably enhance the appearance of a property and can even add to its value.

The huge variety of different designs and the various construction materials available mean that there are many options for all property types, ages and sizes.

Wooden gates are still very popular and have a great natural look that many love. It also works well with more traditional property styles.

Iron gates can be very imposing and are often seen on longer drives. They work well with larger properties and at the entrance to estates of houses.

Both wooden and iron gates can be painted to match existing colour schemes, but the natural wood-look is often retained with wooden gates.

However, iron gates will rust, and wooden gates will rot and crack if they’re not looked after. In both cases, neglecting regular maintenance of these gates can end up making a property look worse, not better.

However, iron gates will rust, and wooden gates will rot and crack if they’re not looked after. In both cases, neglecting regular maintenance of these gates can end up making a property look worse, not better.

More modern options include aluminium gates that can be made in styles and finishes that mimic either wood or iron.

Aluminium gates have decreased in price over recent years thanks to modern manufacturing techniques and improvements in surface coating technology. They’re becoming much more popular as they are lighter, corrosion resistant and need much less maintenance than wooden or iron gates.

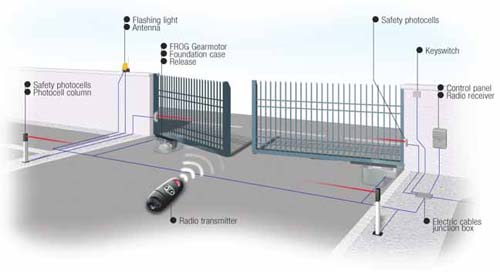

A gate automation system designed to open and close swing or sliding gates automatically comprises a variety of components.

This should always include motors that move the gates, safety devices that are positioned and set up to stop moving gates injuring anyone or damaging property, and devices for controlling when the gates open and close.

Transmitters, remote controls, gate remotes or remote fobs are all names for the hand-held controllers used to open and close automated gates.

The number of buttons on a transmitter corresponds with the number of channels the remote has and the number of indiividual operations the remote can control.

Access control systems add more options for gate control.

The simplest access control system is a button positioned outside the gates. This rings a bell or sounds a buzzer in the property when pressed. Another button inside the house operates the gates when pushed.

When instructed by remotes or access control systems, gate motor controls operate the motors which open and close gates.

Electric motors or hydraulic systems are both used for swing gates while sliding gate motors are all electric. Swing gate motors turn gates through at least 90 degrees on gate post hinges, and sliding gate motors push and pull a single gate along tracks laid across the drive entrance.

Moving gates can be large and heavy and can cause injury and damage if they hit someone or something.

Removing possible dangerous situations involves physically preventing access and using electronic safety devices.

These include pairs of safety photocells that emit an invisible bean of light.

If the beam is interrupted so the receiving photocell doesn't detect the beam, it immediately signals the gate controls to stop the gates.

Once you’ve selected the design, finish and construction material for your gates, the next major consideration is their automation and whether you choose swing gates or sliding gates.

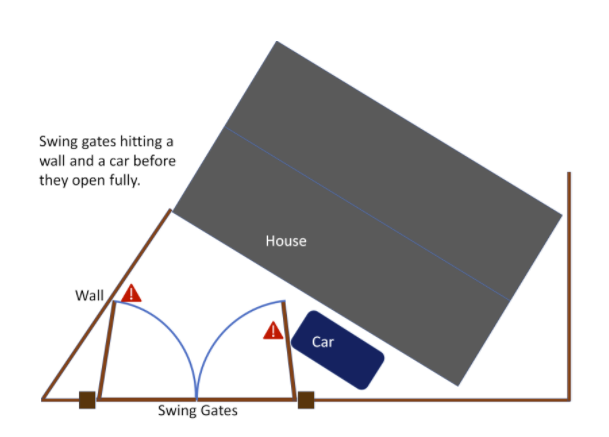

Each swing gate travels through an arc inside the gate entrance. This means that the area they travel through must be free from any obstacles.

Cars can’t be parked in this area and the presence of immobile obstacles such as the house, flower beds, sheds, walls or fences prevent the installation of swing gates.

Similarly, if the driveway rises inside the gates, swing gates will hit the ground at some point. There are hinges that open swing gates at an angle to accommodate rising drives but these put additional strain on motors.

Alternatively, mounting the gates on traditional hinges so that they don’t hit the drive as they open requires a large gap below the closed gates.

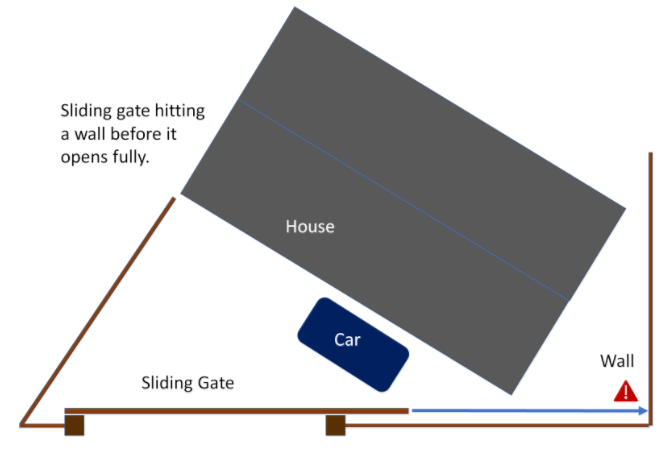

Sliding gates slide across the gate entrance, so they often simply slide along a wall or fence to one side.

However, if this wall or fence angles onto the property within the distance the gate requires to completely clear the driveway entrance, it prevents the installation of a sliding gate.

Sliding gates run on tracks mounted into the driveway and run on visible wheels beneath their base.

One option for avoiding visible wheels and driveway tracks is to use cantilever gates. These still slide open but they don’t need a track so they also don't need wheels.

Instead, the length of gate that slides into place across the driveway entrance is counterbalanced by a length that remains behind the gate motor and rolling support.

In the image of a closed cantilever gate, the left part of the gate covers the gate entrance while the right part is the balance.

Both sliding gates and cantilever gates have a toothed rack mounted along their inside face. The gate motors use a toothed cog mounted on the motor output shaft that meshes with the rack on the gates.

Operating the motors turns the cog which slides the gate open or closed depending on the direction of the motor operation.

Sliding gate motors should apply the same force to open and close sliding gates. This means that sliding gates should not be mounted on slopes as gravity makes it harder to push the gate uphill and tries to accelerate the gate as it slides downhill.

Swing Gate Motors

Swing Gate Motors

Swing gates use motors fixed to the static pillars, posts or in the ground. They have an arm that connects them to the gate. The motor moves the arm which pushes or pulls the gate open or closed.

As the gate is effectively a lever, less force is required to move the gates if the arm is mounted on the gate further from the hinges. If the gate motor arm attaches to the gate nearer the pivot point (hinges), a larger force is required to move the gates.

Unlike sliding gate motors, the principles of swing gate motor operation vary. The following lists the various swing gate motor styles, their operation principles and their strengths and weaknesses.

Ram motors’ long, thin bodies and arms provide a relatively unobtrusive gate automation installation. The motor body contains a hydraulic piston that is pushed out of, and pulled back into the body during operation.

The end of the motor body is attached to the gate post or pillar and the end of the piston arm is attached to the gate. With the piston full retracted, the gate is open. The gate is closed by pushing the piston out of the motor body.

Hydraulic rams are quite an efficient method to automate gates as the piston arm mounts to the gate a good distance from the hinges. However, as the assembly is affected by oblique pressure on the piston, the installation has to be aligned carefully.

If hydraulic rams leak, they lose operational force, so they should be inspected every six months by a professional. All swing gate motors need regular lubrication of motor mounting points.

Swing Gate Linear Screw Motors

Swing Gate Linear Screw Motors

Linear screw motors often appear to be just a long, slim motor housing with no arm. However, the arm is contained within the motor housing and is a threaded shaft. This can be seen through a wide slit in the gate motor housing.

The gate attachment point is internally threaded and mounted on the threaded arm. The gate motor rotates the threaded shaft and because the mounting point is fixed to the gate, it is screwed along the shaft and pushes the gate open or closed.

Like rams, linear screw motors need careful alignment during installation. They are also strong motors capable of automating large and heavy gates.

Articulated arm motors have a jointed metal arm attached to a motor output.

The motor housing is mounted to the gate post and the end of the arm is attached to the gate. When the motor turns, the articulated arm opens or closes the gate.

Articulated arms tend to be a little more tolerant of slight installation inaccuracies than rams and linear screws.

Also, like rams, the gate mounting is further from the gate hinge, so less force is required to open and close gates.

Articulated arms use a jointed arm that closes up as the gate opens. This can trap anything caught in it and should be considered when planning gate automation safety.

Underground motors are discrete gate operators that are sunk into pits beneath the gate hinge axis.

Arms connected to the hidden gate motors are then attached to the base of the gate. As the body of the motor is below ground level under a housing cover, undergrounds are very discrete.

However, the underground location also makes them prone to water damage unless sufficient drainage is provided. If an underground gate motor is submerged in water for a short period of time, it will fail.

Underground motors require careful installation and require a lot of force to operate gates, as the motor output shaft is in-line with the gate hinges and the arm mounts close to the hinge point. They use electric motors or hydraulic systems and need regular inspection for optimum operation.

In-post motors are discrete motors installed within (usually) specially constructed gate posts. Arms connected to the hidden gate motors are then attached to the base of the gate.

This makes in-post motors similar in operation to undergrounds but without the requirements for drainage. They do however, need to be strong to operate gates as their arms are also mounted on the gates close to the pivot point.

There are fast versions of gate motors, and the manufacturer Nice has a range of High Speed swing and sliding gate motors. However, there is a difference in the distance travelled by swing and sliding gate motors, so like-for-like motors will open one faster than the other.

With a 4m gap between pillars, a sliding gate moves more than 4m, while the opening edge of each swing gate moves 3.141m to open 90 degrees. Despite the differences in motion type (sliding vs rotating) and motor action, swing gates are slightly quicker to open because of this.

A risk assessment should be carried out as part of the design of every gate automation system. This looks at the physical aspect of the installation, operation requirements, who will have access and where any possible danger areas exist.

A qualified installation engineer knows that sliding gates move across stationary surfaces so have the potential to cause shearing and crushing injuries. They will also understand that swing gates can cause pinching and crushing injuries at the hinges and impact and crushing injuries as the gates swing open.

Many electric gate motors have obstacle detection in-built. This means that if the electric gate hits an obstacle, it stops and reverses operation.

Whatever motors are used, a professional gate automation installer will ensure that your requirements are met from a safe automated gate system.

Because there is no regulating body for gate automation, anyone can legally install gates and automate them. However, that installer is then liable for the safety of those gates and can be held responsible for injury or death caused by their automated gate installation.

Badly designed and installed electric swing gates and sliding gates have caused significant injuries and fatalities, so it’s important to highlight the issues faced by the inexperienced installer.

Some manufacturers of gate automation kits and motors advertise their equipment as DIY. This is designed to show that the systems can be installed relatively easily and that they do not require a highly detailed set-up of the system controls.

However, this does not take gate automation safety into consideration. An experienced gate installer should be up to date on safety techniques and requirements so that they can install a fully functioning, safe automated gate system.

An electrician is perfectly qualified to work with electricity. A landscape gardener knows how to prepare groundwork and build foundations for pillars. And a security system installer can assemble a bespoke security system from individual components.

These are all skills required to install electric gates, but none of trades people described above work with the specific safety issues faced by the electric gate installer.

Any electric gate kit can be installed in an unsafe gate automation system, so it is always advisable to have a qualified engineer install automated gates.

By building a bespoke gate automation system from individual components, an electric gate installer is creating a new piece of machinery. This is made up from the gate automation system, the gates themselves, gate posts, safety systems and access control equipment.

By building a bespoke gate automation system from individual components, an electric gate installer is creating a new piece of machinery. This is made up from the gate automation system, the gates themselves, gate posts, safety systems and access control equipment.

This ‘machine’ is unique as it is the only one built at that location with that combination of components for that specific amount of use by those specific individuals. And therefore, it has a unique set of potential safety issues.

Generally, the risks are grouped into different types of potential injury including crushing, impact, drawing in, shearing, hooking and cutting.

Injuries could be caused by contact with the moving gate or in conjunction with the moving gate and another object such as gate posts, metal railings, motor arms, walls or parked vehicles.

Swing gates should ideally swing inward so that they don’t swing out onto pavements or even into roads.

A sliding gate should not be installed on a slope as this can overload the motor. And a very wide opening may present issues with gate size and weight. In these cases, folding or concertina gates can be considered rather than sliding or swing gates.

There are complex British Standards intended to help with the identification of potential risks, and every new powered gate installation must comply with the Machinery Directive 2006 /42/EC.

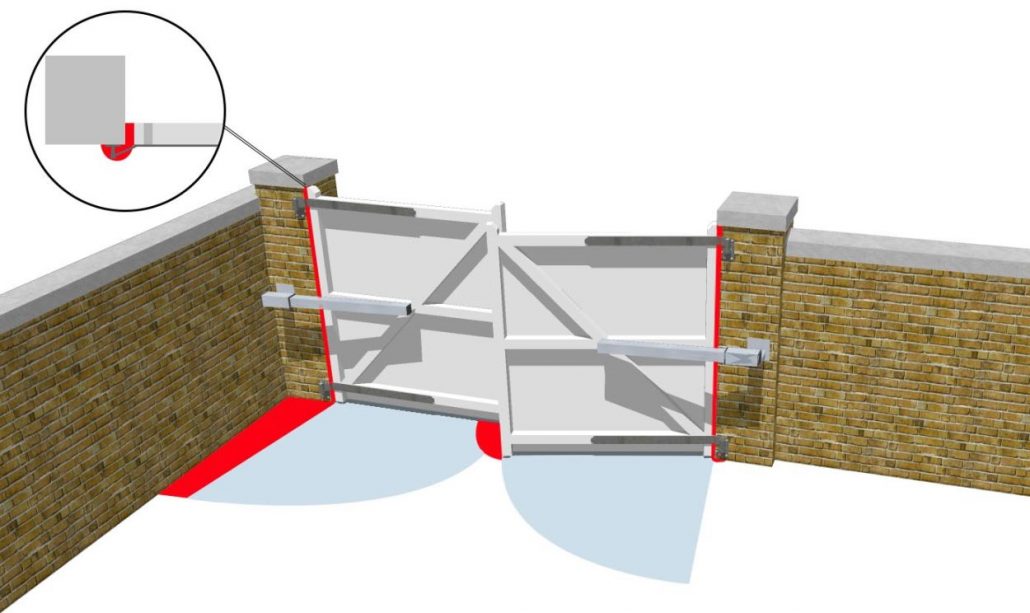

These give gate installers a ‘set of rules’ to use to make gates safer. Step one is to employ methods to prevent access to potentially dangerous areas. These include physical barriers such as wire mesh and cages.

Step two involves the use of electronic safety devices that don’t need the gates to hit anything before they change the movement of the gate. A typical example of this safety measure could be the use of safety photocells. Here a beam of invisible light is broken if someone passes between two photocells into a danger area created by moving gates. The photocells send a signal back to the gate controller which is programmed to stop the gates and even reverse them so there is no contact.

Finally, in areas not covered by physical access prevention or electronic non-contact methods, electronic measures that stop gates if they hit something should be employed. These include safety edges installed on the gates and the use of gate motors with built-in obstacle detection.

Having gates come into contact with anyone or anything should be avoided through the use of the first two methods of gate safety. However, if contact is made, safety edges and obstacle detection will stop the gates and reverse their action away from the impact point.

These principles allow a qualified gate installer to carry out a safety audit on their proposed automatic gate system plans. The goal is to identify the possible risks and develop safety measures to eliminate them. Additional training on the safe use of a new gate system should also be provided to the owners. However, training is not a substitute for safe gate design, as untrained users, such as visitors, will come into contact with the gates regularly.

The safety audit will consider risks posed by:

These factors will also influence the selection of appropriate gate motors that will not be stressed in use.

Other important considerations include:

Before motors are installed, the geometry of a system is checked to ensure smooth, unobstructed movement of the gates. Swing gate need to move freely on their hinges and a sliding gate must run smoothly along its track.

Gate safety can comprise of a combination of physical guarding, photocells, safety edges, electric gate motors with obstacle detection, signage that explains safe operation of the gates and manual release systems.

All electric gate installations should have a manual release system. This allows the gates to be disconnected from the gate motors. They can then be moved by hand in the event of a power failure, breakdown or in an emergency.

All users of the gates should be taught how the manual release system works and where the manual release key is kept.

One of the simplest ways to ensure on-going safe operation of automated gates, within the parameters established through a safety audit, is to keep them working at their best. Electric gates should ideally be serviced annually or twice a year depending on how frequently they are used and what safety devices have been installed. Due to the importance of their correct operation, photocells and safety pressure edges should be regularly checked.

The individual components that make up a gate automation system are varied and often complex. Electric motors or hydraulic drives operate gears connected to arms or brackets fixed to your gates. Modern electronics are used in control panels, photocells, loop cards, safety edges, access control system and transmitters and receivers.

It doesn’t matter what combination of sliding or swing gates, control panels, motor voltages, safety devices and access control is used. Maintenance is vital to ensure that automated gates work smoothly and safely, and to reduce the possibility of expensive and time-consuming automatic gate system breakdowns.

The frequency of maintenance for any gate system may be affected by the frequency of use of the gates.

Electric gates that are opened and closed all day long are more prone to wear-related issues than gates that open once or twice a day. But gates that aren’t used for a few days at a time may need more servicing that focusses on keeping components moving freely.

Location of a gate automation system may play a part in determining how much servicing is required. If the gates are near the coast, strong winds and salt spray from the sea can reduce service intervals.

But the essence of good gate breakdown preventative maintenance is a service from an experienced gate installer at least once every year.

Ideally, the gate engineer who installed a new gate automation system will advise on the level of servicing. For anyone who has moved into a house with automated gates and is unsure about their service history, calling a qualified local gate engineer is a wise move. They will be able to assess the overall condition of the gate automation system and carry out any required servicing and maintenance work.

A good electric gate engineer will carry out regular maintenance that includes:

There are also a few things owners of gate automation systems can do themselves to help reduce maintenance requirements. Manual release devices should be operated three or four times every year to keep the mechanism from seizing due to lack of use.

The area around automated gates should be kept clean and free from debris, loose stones and any snow and ice. In areas prone to slug damage slug traps, pellets or slug wool can be used to keep slugs away from vulnerable electronic circuit boards. Gravel laid below the control box will also help to deter slugs.

Gate automation provides a convenient and stylish way of having beautiful gates at the entrance to your home without the hassles of operating them manually. They make a great first impression for visitors and provide a secure environment for the family away from the dangers of local roads.

The huge variety of gate styles and colours ensures that gates that compliment any house are available. Modern manufacturing techniques mean that corrosion-resistant materials like aluminium are available in gate forms that mimic wood or iron gates at prices comparable to the originals.

Gate safety is widely understood amongst qualified engineers. Fears that automatic gates are dangerous can be put aside by ensuring that automated gate systems are designed, installed and maintained by professional installers.

3 Comment(s)

It did catch my attention when you talked about how aluminum gates require less maintenance and are lighter than wooden or iron gates. My husband and I are planning to install a gate automation system in our house, so we're looking for the best material for it. We're both busy, so we only want to choose an automatic gate that will not demand heavy maintenance. Thanks for sharing this.

Thanks for posting the useful information to my vision. This is excellent information,.

I figured that opening and closing an automatic gate all day would cause more wear, but I didn't realize that not using a gate for days at a time would be a problem. My husband and I have a new home with a gate, and we usually just have to leave it open all the time so he doesn't have to get out of the car to open and close it, so an automatic gate would be handy. We'd use it fairly regularly, as he goes to work and I take the other car for groceries, but I don't think we'd end up opening and closing it more than four times a day on average, so I don't think wear or idleness would be a huge issue for us as long as we kept it maintained properly.

Leave a Comment